Projektinitiativ #54: The end of poor internal quality in the continuous casting of steel slabs? ( 3 kommentarer)

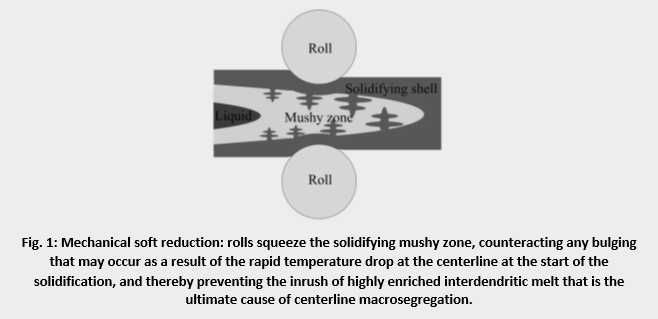

The Swedish steel industry has long been preoccupied with the twin problems of centreline macrosegregation and porosity that occur in the continuous casting of slabs. At various times, at various sites and for various steel grades, these problems have been significantly reduced by the use of mechanical soft reduction (MSR), the principle of which is illustrated in Fig. 1. Nevertheless, these internal quality issues still persist, not just in Sweden but worldwide [1-3].

The challenge in using MSR in a proper way is to keep track of the position of the metallurgical length, which varies with casting speed, mold cooling, secondary cooling and material properties. However, even for this, there is no universal agreement between results of models and experiments, nor necessarily even between results obtained using different experimental techniques: for example, Electro Magnetic Metal Acoustics (EMMA) and pressure difference measurements. It is also essential that the adjustment of the squeezing segments is done according to a schedule that is unique for different families of alloys.

This project combines industrial trials, using different measurement methods to determine the metallurgical length, laboratory measurements (DTA, DSC to obtain solidus and liquidus temperatures and latent heat values for selected alloys) and modelling. The project target is to provide an experimentally validated, common and easy-to-use quantitative decision-making tool for the prevention of central macrosegregation and porosity.

References

- S. Luo, M. Zhu and C. Ji (2014) Theoretical model for determining optimum soft reduction zone of continuous casting steel, Ironmaking & Steelmaking, 41:3, 233-240.

- S. Luo, M. Y. Zhu, C. Ji and Y. Chen (2010) Characteristics of solute segregation in continuous casting bloom with dynamic soft reduction and determination of soft reduction zone, Ironmaking & Steelmaking, 37:2, 140-146.

- J. Domitner, M. Wu and A. Ludwig (2015) Numerical Study about the Influence of Small Casting Speed Variations on the Metallurgical Length in Continuous Casting of Steel Slabs, Steel Res. Int., 86:3, 184-188.

Projektinitiativet stöds av Jernkontorets teknikområde 24, Gjutning och stelning.

Namn Robert Vikman

Organisation Jernkontoret

Kommentar #1

This project would give more information for soft reduction control.

Namn Agne Bogdanoff

Organisation SSAB Europe Oy

Kommentar #2

Både projekt #54 och #55 är fokuserade på segring och gjutstrukturer. Problemen är mycket komplexa och stor potential finns att öka kvalité, minska ledtider och reducera miljöpåverkan av efterkommande processer.

De verkyg som används idag för att påverka segring bör nogrannt undersökas och kartläggas. Det finns ett stort behov att utveckla en "verkygslåda" med åtgärder för att påverka segring och gjutstruktur.

Namn Teknik Stålverk Avesta

Organisation Outokumpu Stainless AB

Kommentar #3

Intressant projekt då detta kan bidra till att öka inre kvalitén, såsom minska centrumporositet och makrosegring, hos stränggjutet material. Även information om sumpdjupets position är viktigt för att optimera soft reduction (samt även produktivitet). Med ökad inre kvalitet möjliggörs stränggjutning av nya produkter.

Namn Karin H Antonsson

Organisation Sandvik Materials Technology, R&D Metallurgy