Projektinitiativ #61: State-of-the-art modeling tool to study precipitation of intermetallic phases in stainless steels ( 1 kommentar)

The importance of steel industry in the prosperity of Swedish economy cannot be overemphasized. For the high performance stainless steel, the Swedish steel companies are world leaders in their respective product areas with a share of almost 60% of world´s duplex stainless steel production. However, in order to maintain its global ranking and to ensure the top-notch quality of its niche products, which are already being copied worldwide, the stainless steel industries need to continue develop its products at an ever faster pace.

Perhaps the most important key enabling technology for this to occur is the more extensive use of computer modelling to design grades but also to optimize production processes. A decisive factor in determining the quality of stainless steel products is the possibility to form detrimental intermetallic phases such as sigma phase, nitrides, chi phase etc. during production and fabrication processes. The formation of these phases has always been a serious concern, and new more highly alloyed grades are even more susceptible.

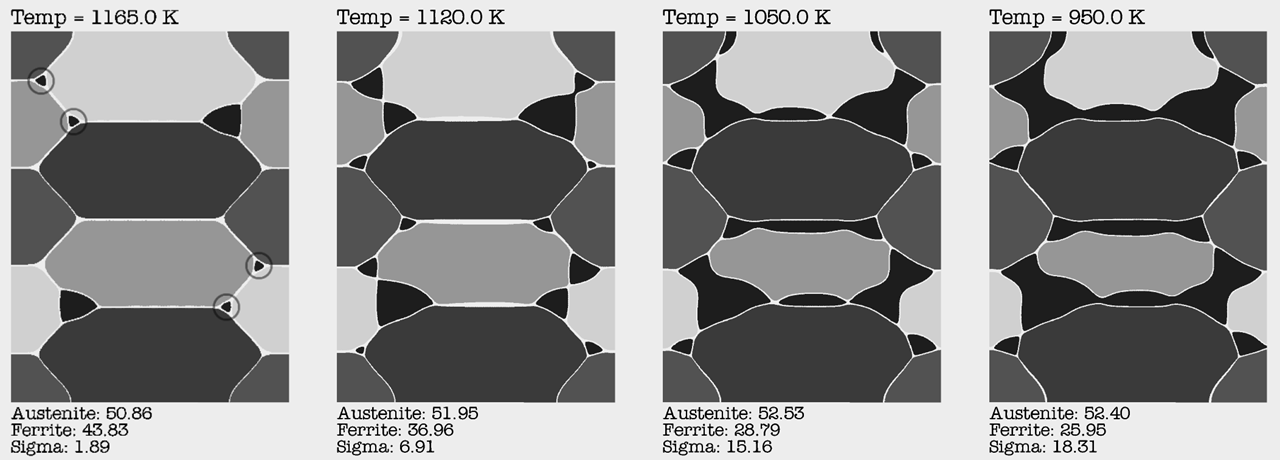

Thanks to the advanced modeling approach viz. the phase-field method, it is now possible to couple the CALPHAD thermodynamic and mobility databases to sophisticated finite element models in order to study complex phase transformations with realistic microstructures and 3D geometries. The idea with the current project is to utilize this powerful approach on the concept of sigma phase formation during processing advanced stainless steels. A successful implementation of this project would then offer predictive capabilities for the production process parameters in terms of i) compositions and ii) time-temperature profiles to avoid the precipitation of intermetallic phases.

Namn Amer Malik

Organisation Swerea KIMAB AB

Kommentar #1

Dear Amer Malik,

There are now four proposals for methods to handle complex phase transformations in engineering alloys (#1, #19, #26 and #61).

The phase-field method (#61) and the GEM (Gibbs Energy Minimization) method developed by myself (#1) both study the total Gibbs energy of the system. Both methods also use optimization to arrive at a solution. The phase-field method work with diffuse phase poundaries while GEM work with mathematically sharp phase boundaries.

I would really welcome a possibility to apply the two methods to the same problem and determine the pros and cons of the two methods. If relevant also the methods #19 and #26 should be evaluated on the same problem.

Such an evaluation should make it possible for our industrial partners to get a better understanding of the strengths and weaknesses of the various methods.

Best regards

Andets Salwén

Namn Anders Salwén

Organisation InnoXinetix