Projektinitiativ #58: Measurement Technic for the future process development ( 7 kommentar)

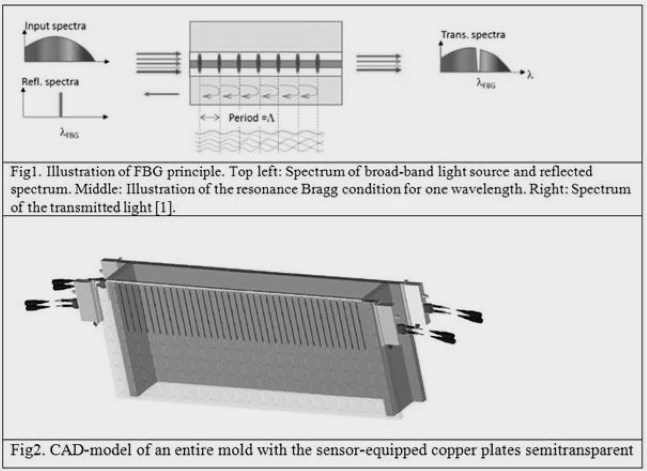

Fiber Bragg Gratings, FBGs are small refractive index modulations that are inscribed in optical fibers. By launching light into the fiber and detect the reflected wavelength of each FBG their respective temperature can be measured. An FBG sensor is the most established fiber sensor technology and the sensors as well as readout systems are commercially available from a number of companies.

The basic technology of fiber Bragg grating (FBG) is an established fiber optic measurement technique that is widely used in the oil and gas industry, but whose prevalence in other industrial sectors generally is very small if compared to the use of conventional thermocouple technology. The main reasons for the established usage for oil and gas applications is the obvious advantages of the fiber optic technology in these harsh environments and that these industries have been willing to take the relatively high cost of developing sensor elements and readout systems. Another reason for the limited use of FBGs is that there exist no real standards for encapsulation and packaging as for electrical sensors, and that FBG-sensor to a high extent needs to be custom made for specific applications.

However, since these costs have fallen sharply in recent years which make the technology attractive for other areas.

The challenge lies in the selection of the type and design of FBGs combined with an encapsulation and packaging method that achieves the high performance and robustness requirements for probes adapted for mould temperature monitoring, and to meet the flexibility needs that research projects such as that for Mould design.

The project will lead to a developed multipoint temperature probe of high importance for further development of optimized mould designs – as well as a better general understanding of the casting process. The optimized process control will enable improved quality and higher yield of the slabs processed. This will contribute to a more sustainable life cycle due to avoiding recasting and by producing a high quality material of extended life length in its end application. Avoiding recasting means reduced energy consumption, increased resource efficiency through material savings, as well as saved costs.

This Project initiative is supported by Jernkontorets teknikområde 24, Gjutning och stelning.

[1] Gunnar Hedin, et al. EXPLORING OPPORTUNITIES IN MOLD TEMPERATURE

MONITORING UTILIZING FIBER BRAGG GRATINGS

Namn Robert Vikman

Organisation Jernkontoret

Kommentar #1

Rise Acreo strongly supports this Project initiative and are also confident that we can provide technical expertise and know-how in order to reach project results that have a wide usage for the industry. Acreo has more than 20 years experience working with FBGs and has also developed high temperature resistant FBGs, so called CCGs which could be of interest in extreme environment. We have also experience on designing and building sensor systems using various types of commercially available low cost FBGs which can be very attractive for industrial applications. In general Acreo have fiber optic material expertise in-house and long experience in working with high temperature applications at steel industry, and would be very interested in discussing this proposal and how we can support it.

Namn Erik Zetterlund

Organisation Rise Acreo

Kommentar #2

Proximion identifies a strong potential for the industry to achieve a new level of insight into the process and thereby process know-how by providing 50x-100x the number of temperature measuring points compared to conventional systems. Proximion is interested in discussing this proposal with Acreo and other stakeholders from the industry. Proximion is focusing on tailored fiber optic sensing systems for harsh environment industries with a need for a high number of sensing elements.

Namn Johan Pejnefors

Organisation Proximion

Kommentar #3

ABB Metallurgy supports this Project initiative. We can also provide support for the use and analysis of the measured results.

Namn Jan-Erik Eriksson

Organisation ABB AB, IAPI/Metallurgy

Kommentar #4

This is interesting topic. New measurements would help process development to improve quality and yield of casted slabs.

Namn Agne Bogdanoff

Organisation SSAB Europe Oy

Kommentar #5

Mycket intressant då det ger ny information om vad som sker i kokillen, såsom värmeöverföring, rätt kokilldesign, gjutpulverfunktion, meniskens utseende osv. Med dessa temperaturmätningar kan processparametrar optimeras för att förbättra kvalitet och utbyte.

Namn Karin H Antonsson

Organisation Sandvik Materials Technology, R&D Metallurgy

Kommentar #6

Intressant teknik som bla kan användas som komplement eller i kombination med vår teknik för nivåmätning i kokillen.

Vår kunskap om nivåmätning samt vår erfarenhet från olika installationer runt om i världen kan passa bra i detta projekt.

Namn Johan Lindvall

Organisation Agellis Group AB

Kommentar #7

Vi behöver metoder för att bättre förstå vad som händer i kokillen och denna mätmetod ger oss ett generationsskifte inom mätteknik. Denna är på väg att lanseras på bred front inom stålindustrin, men vad kan vi lära oss mer? Projektet bör bygga på hur mätmetoderna kan användas för modellering, gjutpulverteori, oscillering och smörjning i allmänhet. Detta kav vara mycket givande för att ta nästa steg inom stränggjutning. Men, att hur en dylik utrustning skall installeras och utformas bör inte vara fokus inom detta forum.

Namn Christoffer Schmidt

Organisation Teknik Stålverk Avesta