Projektinitiativ #41: Thermal vision assisted surface and near surface defect analysis ( 1 kommentar)

Surface quality of steel products has become more and more important during the last 10 years, because the quality of the surface is not only affecting the aesthetic look and cost of the finished product, but also the surface sustainability against many corrosion processes.

Saed Mousavi presents the initiative during the 2017 conference

Therefore many surface quality monitoring systems have been brought to the market and almost all of these systems rely on a visual 2D picture. Since these systems are relying on a visual picture of the surface they cannot function in any harsh environment, and are therefore often placed down the production line as quality insurance measure. In recent years, the fast development of Thermal vision systems has given a new dimension to defect detection on the surface and perhaps near the surface of the product and at early stages of the production lines.

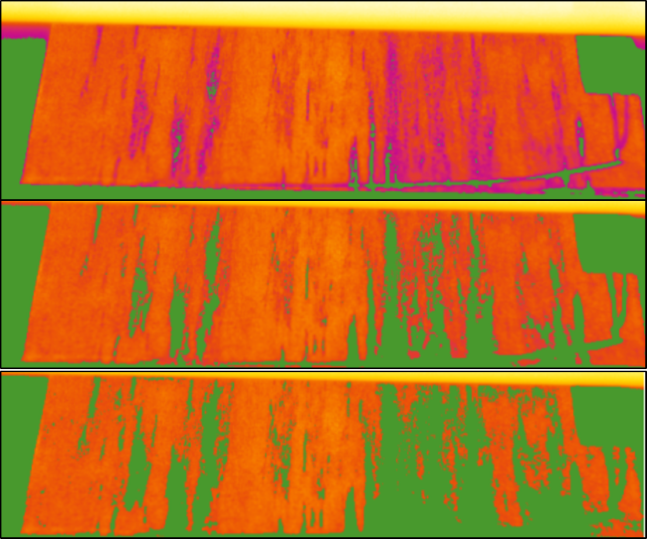

The proposed study is manly targeting the ability of the Thermal vision systems to detect different types of defects at different stages of steel processing (such as hot and cold rolling, forging, additive manufacturing). There are a number of different questions that has to be investigated; what kind of defects are possible to detect, how sensitive will the system be, what kind of post processing of data is needed? Furthermore it has to be investigated if it is possible to combine the Thermal vision data with other types of sensor data to enable detection of defects that otherwise would be hidden to both of the systems? Preliminary tests using Thermal imaging suggests that it is possible to detect oxides on a hot rolled surface (see image).

In the proposed study the capabilities of different Thermal vison systems will be evaluated. The detection of different types of surface defects found at different stages of steel processing will be evaluated. The study will contain experiments and image analysis for detection of different types of defects. The outcome of the study will shed light on the advantages and shortcomings of these systems. A proposal for continuation of use of these systems will be put forward.

This project initiative have been put forward by Jernkontoret's TO44 Oförstörande provninng och mätteknik. The members of the consortium are looking for partners that are interested in further developing the ideas above.

Namn Robert Eriksson

Organisation Jernkontoret/TO44

Kommentar #1

Very interesting proposal where recent IR sensor developments open up new possibilities. Relevant for many different applications and we are interested to participate to explore the feasibility of the technology.

Namn Eva Lindh-Ulmgren

Organisation Swerea KIMAB